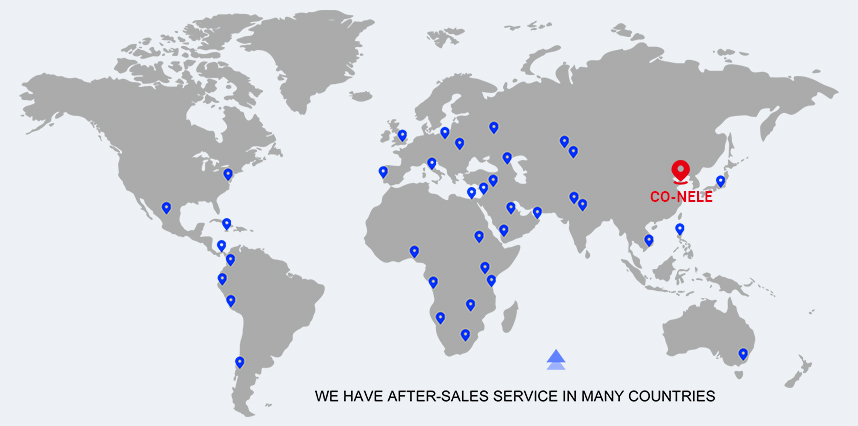

The Pioneer Of China's Mixer Equipment, With 26 years of experience in mixing and granulation technology, CO-NELE has obtained over 100 national technology patents and has accumulated 10,000 users from more than 80 countries worldwide in the fields of intensive mixers, granulator machines, and planetary mixers.

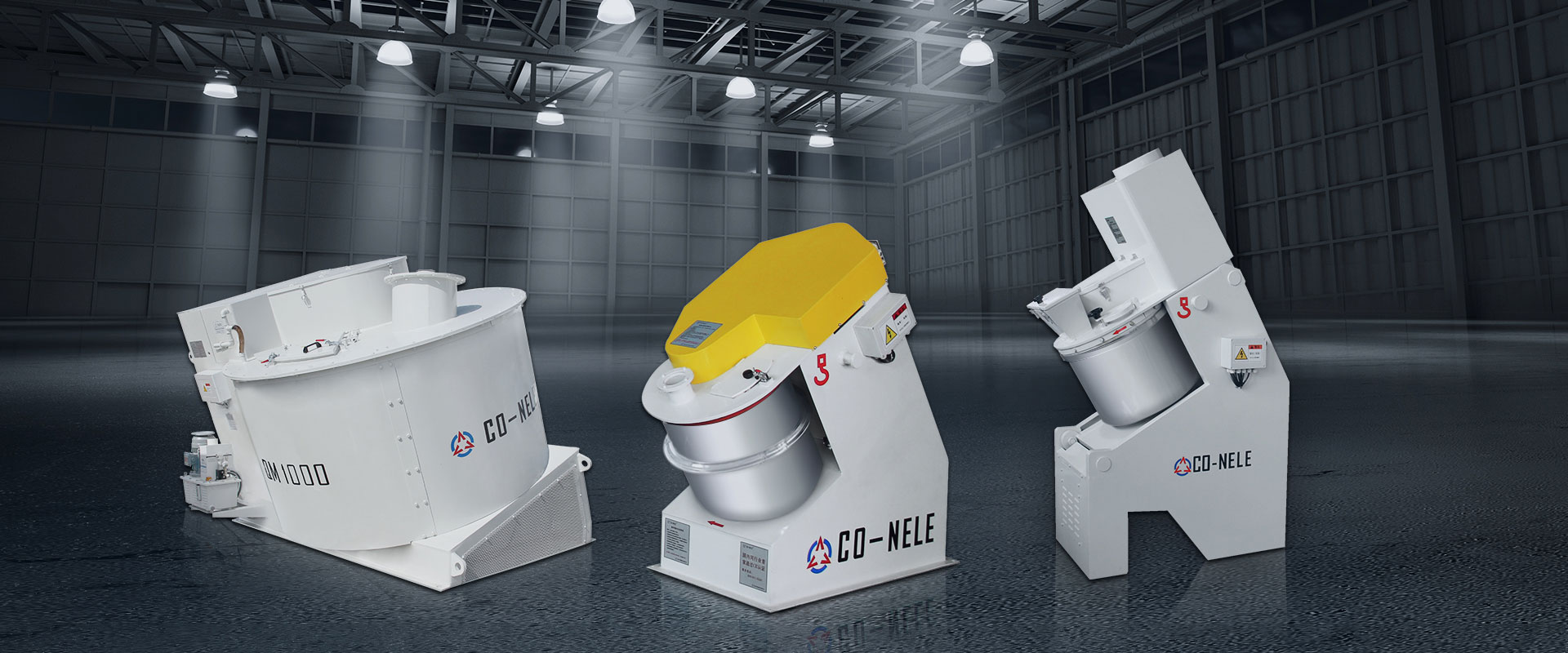

MORE ABOUT CO-NELEIntensive Mixers capacities from 1L to 12000L ,catering to both intermittent and continuous production.

Co-Nele has established close partnerships with over 40 universities.

Just one machine is needed to carry out the two process steps: Mixing and Granulating/Pelletizing

Co-Nele Intensive Mixer is widely used in the preparation of raw materials for mixing, granulation, coating, and homogenization in various industries such as lithium batteries, magnetic materials, ferrites, refractory materials, glass, ceramics, chemicals, foundry sand, compound fertilizers, metal powders, catalysts, molecular sieves, pellets, fluxes, and concrete. Laboratory mixing and granulation machines are also provided, allowing for free trial testing before production.

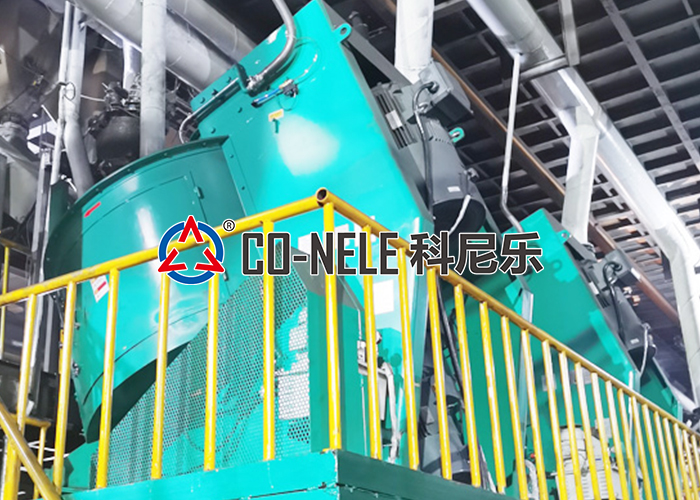

CO-NELE have played an active role in the development of industrial mixing & granulating and pelletizing technology for more than 26 years. The large number of patents our close co-operation with users and our partnerships with research and learning institute have laid the foundation for the excellent reputation of the CO-NELE intensive mixers and planetary concrete mixer.

Refractory intensive mixer is one of the latest mixing equipment developed by CO-NELE. It has ideal mixing effect and superior performance. It is widely used in the refractory industry at home and abroad.The mixer can mix the materials to a uniform effect

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.