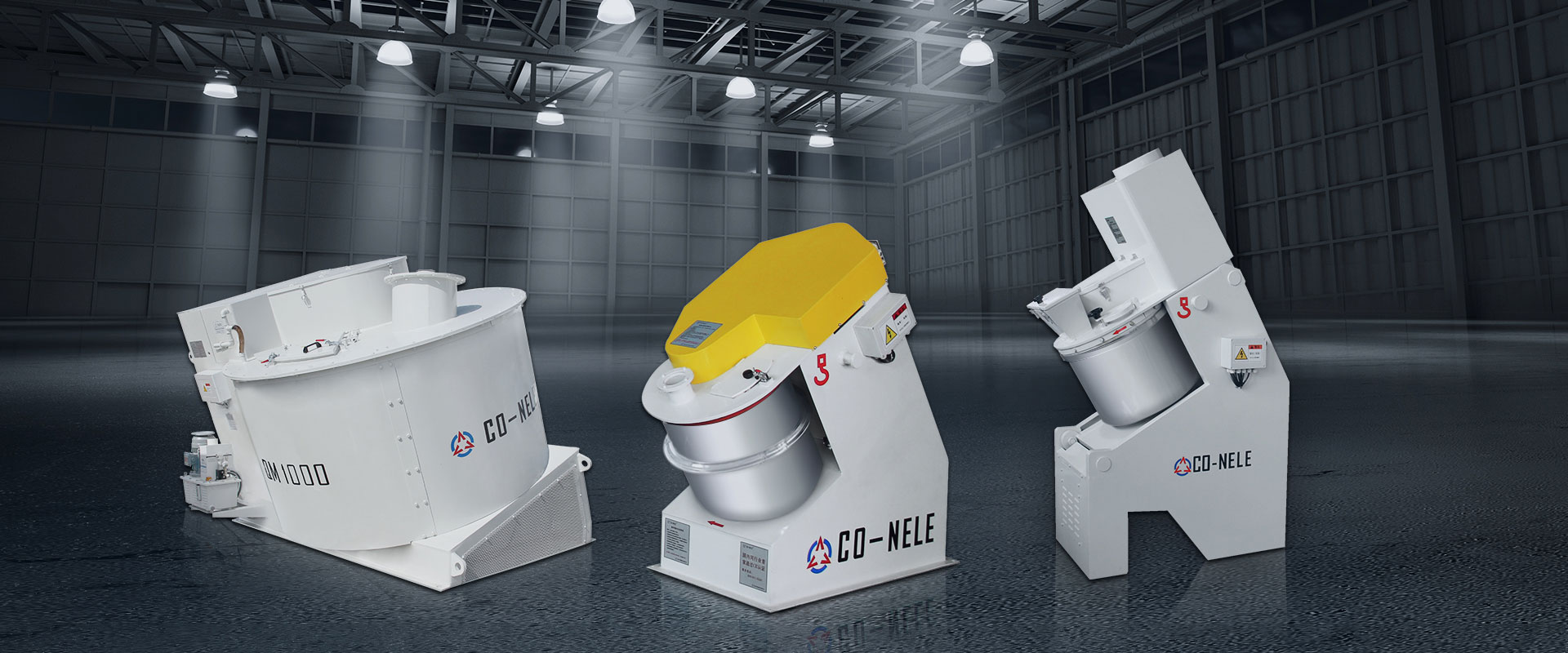

After 26 years of industry accumulation, CO-NELE has obtained more than100 national technology patents and more than 10,000 intensive mixers and planetary concrete mixers.

MORE ABOUT CO-NELEWe Guarantee That Your Request Will Be

Handled Quickly & Appropriately

CO-NELE Can Provide Training Services To

Different Users

We Provide You Detailed & Extensive

Knowledge About Your Machine

The Pioneer Of China's Mixer Equipment, CO-NELE is professional mixer manufacturer and exporter with our own factory.

CO-NELE have played an active role in the development of industrial mixing & granulating and pelletizing technology for more than 26 years. The large number of patents our close co-operation with users and our partnerships with research and learning institute have laid the foundation for the excellent reputation of the CO-NELE intensive mixers and planetary concrete mixer.

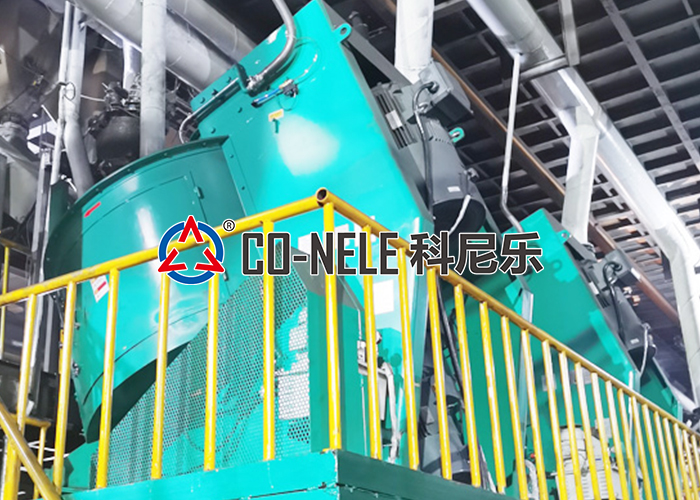

Refractory intensive mixer is one of the latest mixing equipment developed by CO-NELE. It has ideal mixing effect and superior performance. It is widely used in the refractory industry at home and abroad.The mixer can mix the materials to a uniform effect

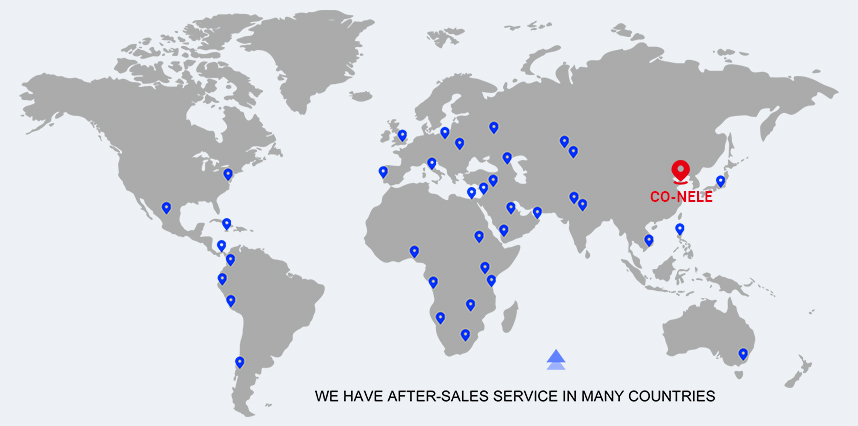

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.