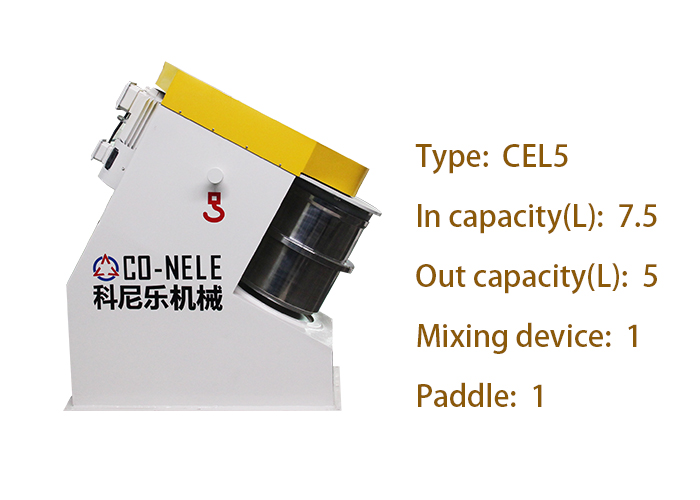

CEL5 Laboratory Mixer With Technical Information

CEL5 laboratory intensive mixer with mixing and granulation (Laboratory Granulator mixer) functions. It can work under cooling, heating (temperature can reach 200 degrees) and vacuum conditions. The laboratory granulation mixer equipment first ensures a small footprint and sufficient internal space in terms of equipment appearance. Secondly, the precision and durability of the equipment meet the high production requirements of laboratory standards.

CEL5 laboratory intensive mixer application: refractory materials, glass products, ceramic aggregates, metallurgical casting sand, environmental sludge, building materials, chemical fertilizers, and even flux, friction materials, and carbon materials.

Here are the technical informations of the CEL laboratory mixer:

The laboratory intensive mixer is an efficient mixing equipment suitable for laboratory environments, with the following characteristics and advantages:

Efficient mixing capacity: It can achieve full mixing of materials in a short time.

Good uniformity: It can evenly distribute materials of different particle sizes and densities to ensure product consistency.

Wide range of applicable materials: It is suitable for various types of materials such as powders, granules, liquids and viscous materials, and is used in many industrial fields such as metallurgy, refractory materials, glass, chemicals, building materials, agriculture, pharmaceuticals, and food.

Precise control of parameters: usually equipped with advanced control systems, which can accurately adjust parameters such as mixing time, speed, temperature, etc. to meet different experimental needs.

High repeatability: can provide stable mixing effects and ensure consistency between different batches.

Promote innovation: help experimenters test different material combinations and mixing processes in the new product development and process improvement stages.

Flexible adaptation: can adapt to the mixing of raw materials of different types, sizes and proportions.

Easy operation: some equipment is equipped with an intelligent operation interface to reduce the complexity of operation.

Recording data: data during the test can be recorded to facilitate subsequent analysis and optimization.

.jpg)

Relying on the CO-NELE CR02 laboratory intensive mixing granulator (5 liters effective volume), through three batches of experiments, our technical team successfully granulated the raw material into uniform spherical particles with a particle size of 2-3

CONELE offers a full range of mixing equipment, from the small CEL1s laboratory mixer machine to the large CRV33 industrial machine, supporting various binder systems including ceramic, resin, and metal, and suitable for various abrasives such as corundum

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.